Low-surfactant emulsification systems represent a fundamental shift in how formulators approach emulsion design. Instead of relying on high emulsifier concentrations to force stability, these systems achieve long-term performance through optimized interfacial architecture, rheology control, and system-level balance. As formulation complexity increases and ingredient scrutiny intensifies, minimizing surfactant load has become both a technical and strategic priority.

This article provides an in-depth analysis of low-surfactant emulsification systems. It explains why conventional emulsions depend on high emulsifier levels, how stability can be achieved with reduced surfactant content, and which design strategies enable robust performance across food, cosmetic, pharmaceutical, and industrial applications.

What Defines a Low-Surfactant Emulsification System?

A low-surfactant emulsification system achieves physical stability using significantly less emulsifier than conventional formulations. While traditional oil-in-water emulsions may rely on 3–6% emulsifier or more, low-surfactant systems often operate below 1%, and in some cases well below 0.5%.

At these reduced levels, emulsifiers alone cannot provide full stability through surface coverage. Therefore, low-surfactant systems rely on complementary stabilization mechanisms such as steric structuring, rheological control, droplet packing effects, and interfacial elasticity.

Why Conventional Emulsions Depend on High Surfactant Levels

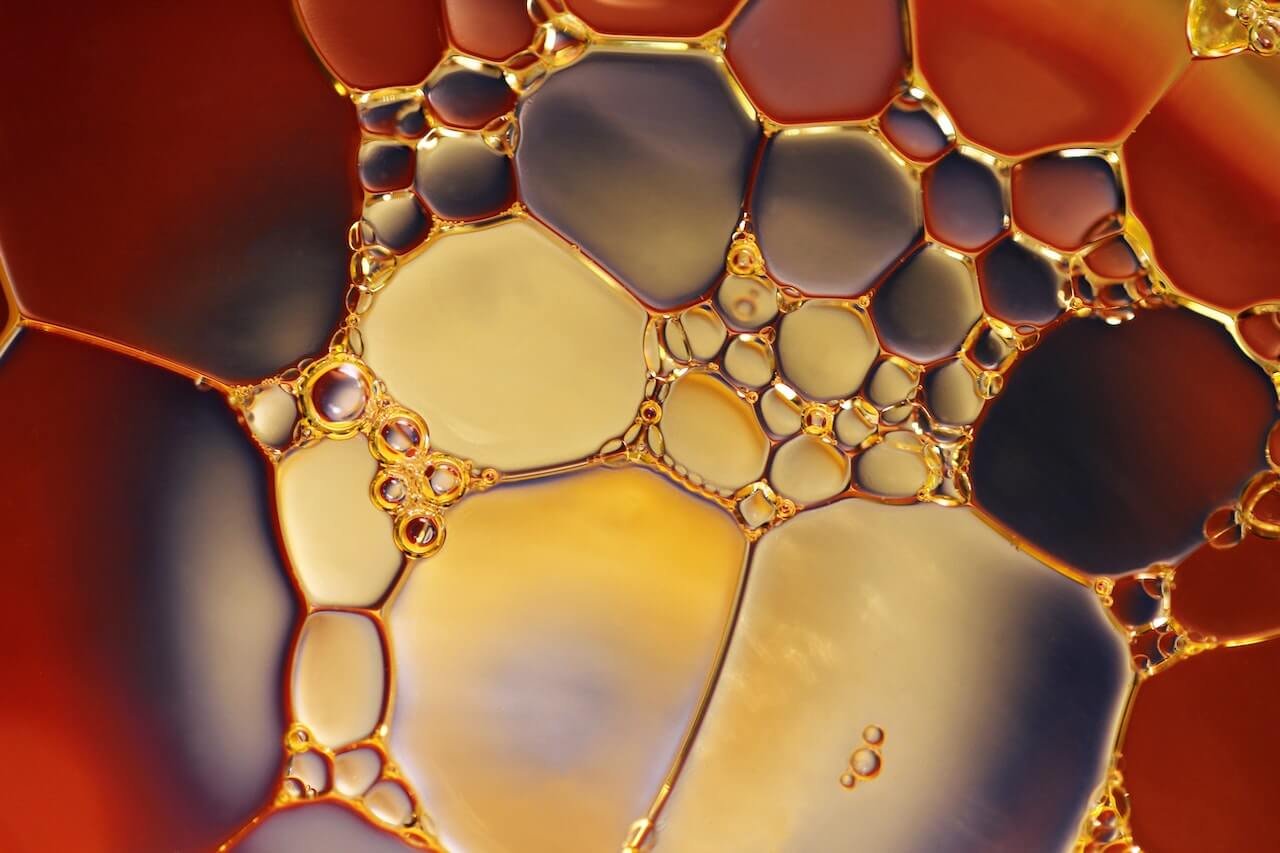

In classical emulsion theory, stability depends on complete interfacial coverage. As oil is dispersed into water, new surface area forms rapidly. Emulsifiers adsorb to this interface, lowering surface tension and preventing immediate coalescence.

When emulsifier concentration is high, excess surfactant remains available to repair damaged interfaces and stabilize newly formed droplets. However, this approach increases formulation complexity and introduces several drawbacks.

High surfactant loads often increase irritation potential, impact taste or odor, alter sensory feel, and complicate regulatory positioning. As a result, formulators increasingly seek stability through smarter system design rather than brute-force emulsification.

Key Challenges in Low-Surfactant Systems

Reducing emulsifier concentration exposes weaknesses that are masked in conventional formulations. Without sufficient surfactant, droplets collide more frequently and coalesce more easily. In addition, interfacial films become thinner and less resilient.

Low-surfactant systems therefore face three primary challenges: rapid coalescence during processing, slow instability during storage, and sensitivity to environmental stress such as temperature and shear.

Stabilization Mechanisms Beyond Surfactants

Steric Stabilization

Steric stabilization relies on physical barriers that prevent droplets from approaching each other closely enough to coalesce. These barriers may consist of hydrated polymer chains, structured emulsifier headgroups, or multilayer interfaces.

Because steric stabilization does not depend on charge, it performs well even when emulsifier concentration is low. However, effectiveness depends on chain length, hydration, and spatial coverage.

Rheology-Based Stabilization

Increasing continuous-phase viscosity slows droplet movement and reduces collision frequency. In low-surfactant systems, rheology modifiers often play a critical role in maintaining stability.

Importantly, viscosity alone does not prevent coalescence. Instead, it complements interfacial stabilization by reducing kinetic energy during droplet interactions.

Droplet Packing and Structural Support

In systems with moderate to high oil content, droplet packing can contribute to stability. As droplets become more crowded, they restrict each other’s movement, creating a pseudo-solid network.

This effect allows some low-surfactant emulsions to remain stable despite minimal interfacial coverage.

Emulsifier Characteristics That Enable Low-Use Levels

Not all emulsifiers perform equally at low concentrations. Certain molecular features improve efficiency and allow stability with minimal usage.

High Interfacial Activity

Emulsifiers with strong surface activity adsorb rapidly and form dense interfacial films. Faster adsorption reduces the window during which droplets can coalesce during processing.

Elastic Interfacial Films

Elastic films stretch and recover when droplets deform. This property becomes critical when emulsifier coverage is sparse, as film rupture cannot be easily repaired by excess surfactant.

Multifunctional Emulsifier Structures

Emulsifiers that also contribute to structuring, hydration, or lamellar organization reduce reliance on concentration alone. As a result, they enable stability through architecture rather than quantity.

Emulsifier Families Commonly Used in Low-Surfactant Systems

Glycerol-Based and Polyglycerol Emulsifiers

Glycerol-derived emulsifiers exhibit strong hydration and flexible interfacial behavior. Their ability to form structured interfaces allows effective stabilization at relatively low use levels.

In addition, certain polyglycerol esters promote lamellar phases that enhance stability beyond simple droplet coverage.

Phospholipid Systems

Phospholipids form bilayers and multilamellar structures that provide structural reinforcement. These systems often achieve stability with minimal surfactant because the interface behaves as a material rather than a thin film.

Biosurfactant-Based Systems

Some biosurfactants demonstrate exceptional efficiency due to low critical micelle concentration and strong interfacial elasticity. When compatible with the formulation matrix, they support low-use emulsification.

Particle-Stabilized Systems

In certain cases, solid particles adsorb irreversibly at the oil–water interface, forming so-called Pickering emulsions. These systems can remain stable with extremely low surfactant content or none at all.

Template Comparison: Strategies for Low-Surfactant Stability

| Strategy | Primary Stabilization | Surfactant Requirement | Main Limitation |

|---|---|---|---|

| High-Activity Emulsifiers | Rapid interfacial adsorption | Low | Sensitive to processing |

| Steric + Polymer Support | Steric hindrance | Very Low | Viscosity dependence |

| Lamellar Systems | Bilayer structure | Low | Composition sensitivity |

| Pickering Emulsions | Particle adsorption | Minimal | Limited sensory control |

Processing Considerations

Low-surfactant emulsions demand precise processing control. Because excess emulsifier is unavailable to compensate for mistakes, droplet formation must occur under optimized shear conditions.

Gradual oil addition, controlled shear ramps, and adequate hydration time improve interfacial coverage and reduce coalescence during processing.

Long-Term Stability Challenges

Initial stability does not guarantee shelf stability in low-surfactant systems. Over time, interfacial films experience fatigue, hydrolysis, or displacement. As a result, slow coalescence or oil migration may occur.

Accelerated testing must therefore include mechanical stress, thermal cycling, and extended storage rather than short-term observation.

Sensory and Functional Advantages

Reducing surfactant load often improves sensory properties. Lower surfactant levels can reduce tackiness, bitterness, or irritation, depending on application.

In addition, low-surfactant systems support cleaner labeling, simplified ingredient decks, and improved consumer acceptance.

System-Level Design Philosophy

Successful low-surfactant emulsification requires a holistic design mindset. Emulsifier choice, polymer selection, oil phase composition, droplet size distribution, and processing conditions interact continuously.

Rather than optimizing individual components, formulators increasingly design the emulsion as an integrated system.

Key Takeaways

- Low-surfactant emulsions rely on system design rather than emulsifier quantity

- Steric, lamellar, and rheology-based mechanisms enable stability

- Processing precision is critical

- Reduced surfactant improves sensory and regulatory positioning