Polyglyceryl emulsifiers are emerging as one of the most important emulsifier families heading into 2026. As formulators move away from ethoxylated systems, they increasingly rely on polyglyceryl structures to achieve stability, sensory control, and regulatory resilience across multiple industries. Consequently, these emulsifiers now function as foundational tools rather than specialty alternatives.

This article provides a detailed technical overview of polyglyceryl emulsifiers, including their chemistry, interfacial behavior, formulation advantages, limitations, and expected role in future emulsification strategies.

What Are Polyglyceryl Emulsifiers?

Polyglyceryl emulsifiers are non-ethoxylated surfactants derived from glycerol oligomers esterified with fatty acids. Unlike PEG-based emulsifiers, they achieve hydrophilicity through multiple hydroxyl groups rather than polyethylene glycol chains. As a result, they avoid ethoxylation-related impurities while offering flexible interfacial performance.

By adjusting glycerol chain length and fatty acid composition, manufacturers can design polyglyceryl emulsifiers with tailored hydrophilic–lipophilic balance. Therefore, this family supports a wide range of emulsion types.

Why Polyglyceryl Emulsifiers Matter in 2026

By 2026, formulators will prioritize emulsifiers that combine regulatory safety, performance versatility, and formulation transparency. Polyglyceryl emulsifiers meet these requirements effectively. Moreover, they align well with clean-label strategies without sacrificing technical robustness.

At the same time, regulatory pressure around ethoxylated materials continues to increase. Consequently, polyglyceryl emulsifiers serve as direct replacements in many reformulation projects while also enabling new texture-driven designs.

Chemical Structure and Interfacial Behavior

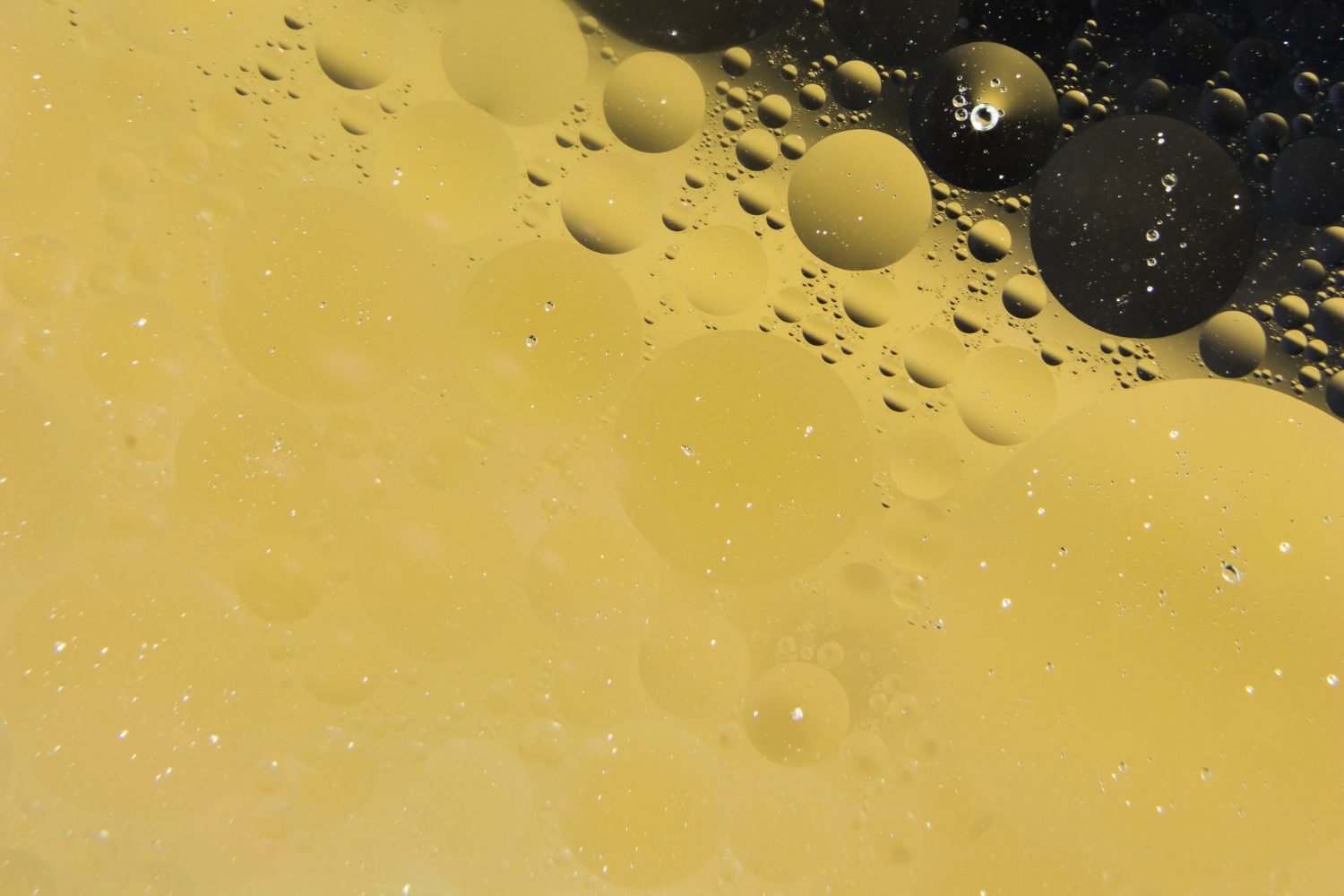

Polyglyceryl emulsifiers consist of glycerol units linked through ether bonds and esterified with fatty acids. This structure creates a highly hydrated headgroup capable of strong hydrogen bonding with water. As a result, these emulsifiers adsorb efficiently at oil–water interfaces.

Unlike PEG chains, polyglyceryl headgroups form compact hydration shells. Therefore, interfacial films tend to be more structured, which influences droplet size distribution and emulsion rheology.

Common Types of Polyglyceryl Emulsifiers

Polyglyceryl Fatty Acid Esters

These emulsifiers, such as polyglyceryl-3 stearate or polyglyceryl-6 distearate, support oil-in-water and water-in-oil systems. Their versatility makes them suitable for diverse formulation environments.

High-HLB Polyglyceryl Systems

Higher-degree polyglycerols increase hydrophilicity. Consequently, they perform well in lightweight emulsions, sprayable systems, and low-viscosity formulations.

Lamellar-Forming Polyglyceryl Emulsifiers

Certain polyglyceryl structures promote lamellar organization. As a result, they contribute to barrier-like emulsions and controlled release profiles.

Formulation Advantages

Polyglyceryl emulsifiers offer several formulation advantages. First, they provide strong stability across a broad pH range. Second, they show relatively good electrolyte tolerance compared to many sugar-based systems.

In addition, many polyglyceryl emulsifiers support cold-process manufacturing. Therefore, they align well with energy-efficient production strategies.

Processing Considerations

Although polyglyceryl emulsifiers simplify reformulation, they still require careful process control. Shear rate, mixing time, and order of addition directly influence droplet size and long-term stability.

In many cases, pre-dispersing the emulsifier in the aqueous phase improves hydration and interfacial coverage. As a result, emulsification becomes more reproducible at scale.

Sensory and Texture Impact

Compared to PEG-based systems, polyglyceryl emulsifiers often generate richer and more structured textures. Rather than avoiding this effect, formulators increasingly leverage it to create differentiated sensory profiles.

Therefore, polyglyceryl emulsifiers play a key role in texture engineering rather than simple stabilization.

Limitations and Mitigation Strategies

Despite their advantages, polyglyceryl emulsifiers may show sensitivity to high oil loads or extreme ionic conditions. However, formulators can address these limitations through system-level design.

Combining polyglyceryl emulsifiers with polymers, secondary emulsifiers, or lamellar promoters often improves robustness. Consequently, successful use depends on holistic formulation design.

Polyglyceryl Emulsifiers in 2026 Formulation Strategy

Looking ahead, polyglyceryl emulsifiers will remain central to PEG-free reformulation efforts. Moreover, manufacturers continue to expand this family with new structures optimized for cold processing, sensory modulation, and sustainability metrics.

By 2026, these emulsifiers will no longer be viewed as substitutes but as primary design tools for modern emulsification systems.

Key Takeaways

- Polyglyceryl emulsifiers are PEG-free and non-ethoxylated

- They offer strong interfacial control and formulation flexibility

- Cold-process compatibility supports energy-efficient manufacturing

- By 2026, they define baseline emulsifier selection